Recycling Industry in Taiwan, Increasing Quality and Output for International Plastic Processing Factories

New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste. With the great importance of recycled-based plastic products, the global demand for plastic recycling is expanding. Recyclers are now purchasing more advanced technologies and much plastic equipment at once, as well as bigger pelletizing extruders. We have different manufacturers having new developments and especially focusing on how to increase the potential as a whole of their machines. Below we mention some examples of manufacturers and their latest developments, all going in the same direction and taking care of what international customers are concerned about, such as an increase in output, multi-purpose recycling machines, higher efficiency, and also lower maintenance costs.

![[Taiwan Quick Facts] After the Pandemic, Taiwan's Plastics and Rubber Manufacturers have Made Remarkable Progress](/UserFiles/company/295/blog_pic/blog_1663918011.png)

[Taiwan Quick Facts] After the Pandemic, Taiwan's Plastics and Rubber Manufacturers have Made Remarkable Progress

After the outbreak of the pandemic, although many orders of products and equipment were affected and delayed, there were some manufacturers became beneficiaries. For example, the pandemic prevention products such as masks, plastic gloves, or medical-grade parts saw a dramatic rise in the production industry. In the past three years, business travel and visits around the world have ceased almost entirely. Many Taiwanese companies have utilized this period of time to invest in manpower and resource research and development, which will be demonstrated in this year's K Show. *High-precision Die Processing Capability, GMA Wins the Favor of European Customers *Botheven Machinery Launched the Market's First Innovative Knitting Machine, which is More Automated and In Line with the Modern Trend *Quick Reaction, from a Stationery Machine Manufacturer to an Expert Mask Machine Manufacturer *Focus on the Design of each Unit, Stacking out the Big Upgrade of the Machine *From Transportation Protective Buffer Material to Electronics, Agriculture, and Stationery, Bubble Film is Widely Used *Proportional Valves Suitable for Various Industries to Supply the Needs of Industry 4.0 and the Medical Industry *PAL Breaks Through the Sealing Melting Point of Biodegradable Materials, Accurate and Stable

POLYSTAR: Recycled Plastic Pellets from PP Raffia and Woven Production – Tips to Reuse them Better

Which recycled plastic pellets should go back to PP tape extrusion line? On average, a 5-10% production waste is generated during the PP woven bag making process at different stages of the production: extruder start-up lumps, waste due to blockage in extruder die head, tape winding, circular loom (weaving defects), coating/lamination stage, pp woven/FIBC bag conversion and printing.

Plastic Recycling Continues to Grow Worldwide

The packaging film sector (stretch film, CPP film and etc.) and plastic bag producers are required to use a much higher percentage of recycled pellets in the end products. For better quality control and to maximize the reusability back into the film extrusion lines, more producers have decided to recycle all the production waste internally instead of outsourcing it.

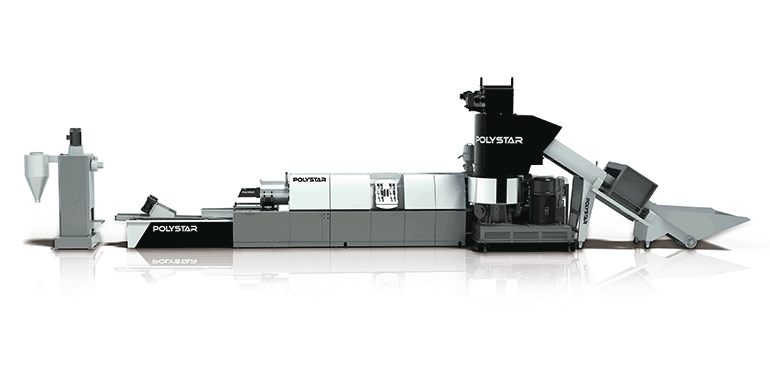

Recycling Machine Sales Doubled for POLYSTAR in 2021

New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. Instability of raw material prices and supplies also forces plastic producers to better recycle their own production waste. The growing demand for plastic recycling directly reflects the machine sales for POLYSTAR.

Chi Chang Machinery, Recovering and Serving Customers After the Beginning of Pandemic

During 2020, there were many challenges where most of industries didn’t know how to face it at the beginning. This 2021 has been different for most industries, since there was already one-year experience with the “new normality” of COVID-19.

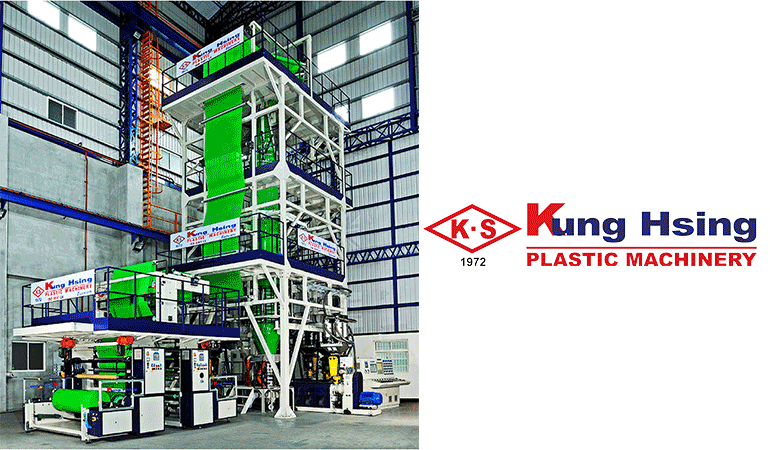

KUNG HSING: 5 Layer Blown Film Co-Extrusion Line Guide - 2021 Buying Tips, Advantages and Popular Models

Kung Hsing Plastic Machinery, established in 1972, is a leading manufacturer in the design and manufacture of Extrusion Machinery. They include PP/PE Inflation (film blowing) making machine, Nylon/Polyester/PP/PE Monofilament making machine, PP/PE Flat Yarn (Woven Bag) making machine, PP packing band machine, PP Sheet making machine and Plastic Recycling Machines. Our machines have been sold to more than 100 countries and approved by many experienced manufacturers in the plastic processing industry.

POLYSTAR - How to Obtain Excellent Quality Plastic Films for Lamination?

Laminated film is an excellent application for packaging food like coffee, snacks, cookies, nuts (peanuts, pistachio, almonds), and others. It is ideal for packaging because laminated films have protection from humidity, oxygen, aromas, fats, and light. All these factors decompose or reduce the lifetime of the packaged product. For this reason, the protective barrier is the most important element in the laminated film, which is composed of PE (LDPE), BOPP, PET, and others.

KUNG HSING: Innovating the Market with their 5 Layer Blown Film Co-Extrusion Line

Nowadays new changes in the Industry are a must for companies, especially if they want to stay at the vanguard in the industry. Kung Hsing is well known for their constant innovation, this time they have the 5 Layer Blown Film Extrusion Line which is the main trends to substitute the 3 layers.

ABA Blown Film Machine – What’s the advantage?

For PE bag production, single layer blown film machine has been the most common type of extruder to use. It is probably still the best machine for products such as fruit and vegetable bags (perforated bag-on-roll) that use mainly virgin materials with low film thickness ranging from 6 to 18 microns. Single layer machine is also the favorable choice for biodegradable bag production.

Taipei Pack 2020 - POLYSTAR Provides Simple Recycling Solutions for Flexible Packaging Film

POLYSTAR will demonstrate its latest developments on pelletizing technology during the upcoming exhibition Taipei Pack 2020, providing simple yet efficient recycling solutions for a wide range of industrial waste from the plastic packaging sector

Chi Chang Machinery Meeting the Highest Quality Standards for Almost Half of a Century

Nowadays one of the main concerns is finding reliable and experienced suppliers for different kinds of machines. Taiwanese companies are famous for its performance and service quality. One manufacturer that must be taken into consideration is CHI CHANG MACHINERY CO.,LTD (CCM), a company with almost half a century of experience in the industry, founded in 1972.